Understanding Flex PCB Design Considerations for Worldwide Applications

By Avanti Circuits in Manufacturing on August 23, 2023

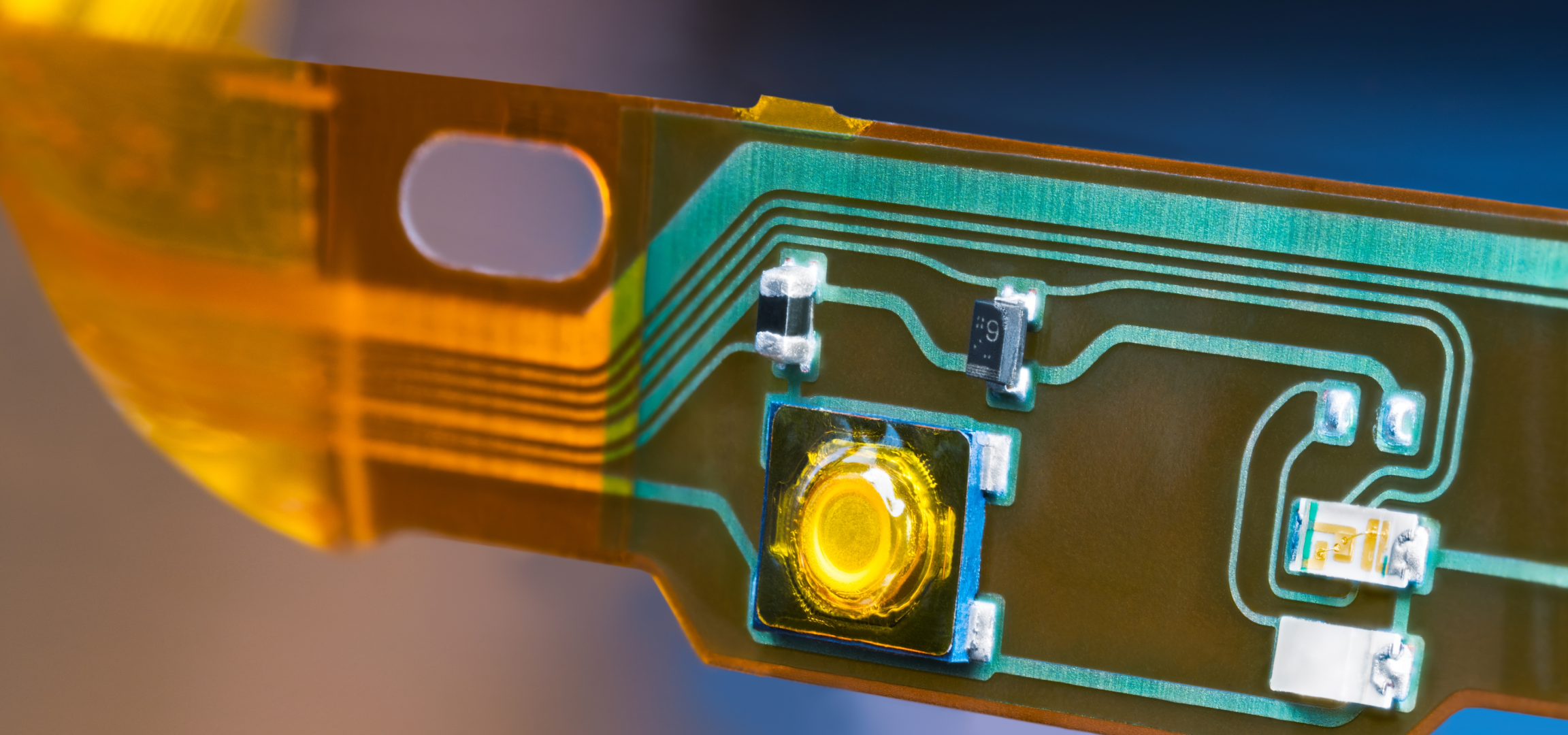

Printed Circuit Boards (PCBs) have revolutionized the electronics industry, and flex PCBs are no exception. Their flexibility and reduced weight make them indispensable in modern applications, from wearables to aerospace. However, their design requires meticulous attention to ensure performance, durability, and adherence to global standards. This article delves deep into flex PCB design considerations and showcases how Avanti Circuits leads the charge in providing high-quality solutions.

Why Flex PCB Design Considerations Matter

Flex PCBs, with their adaptability and compactness, find their way into numerous advanced electronic applications. However, the very characteristics that make them unique also present unique design challenges. Ensuring longevity, adhering to industry certifications, and averting potential costly redesigns underline the imperative of proper design considerations.

Ensuring Product Longevity and Reliability: A robust design can withstand the wear and tear of daily use, especially when the PCB is expected to flex frequently.

Meeting Industry Standards and Certifications: For a company with global aspirations, it's crucial to meet international standards, ensuring products can be marketed and used worldwide without hitches.

Avoiding Costly Redesigns and Manufacturing Issues: Proper design from the outset saves time and money, preventing resource-intensive iterations.

Top Factors Influencing Flex PCB Durability and Performance

Material Choices

Different applications might require distinct substrate materials. While polyimide is common due to its thermal stability, certain designs might benefit from alternatives. Similarly, copper thickness can influence the board's flexibility and performance. At Avanti Circuits, we provide guidance on selecting the best materials aligned with your project needs.

Component Placement

Balancing components ensures the board doesn't have uneven stress, especially vital for flex PCBs. Avanti's design grid offers tools to aid in optimal component placement.

Track Geometry and Routing

Flex PCBs can be sensitive to track widths. Wider tracks can enhance durability, especially around bend areas. Proper routing also prevents unnecessary stress, and our PCB design grid makes this task streamlined.

Stackup Configuration

Symmetrical stackups can prevent board warping. Moreover, when dealing with multilayers, it's crucial to understand how each layer interacts. Avanti's expertise in multilayer PCB ensures designs are robust and ready for varied applications.

Avanti Circuits' Approach to Global PCB Solutions

Competitive Pricing - With Avanti, you’re guaranteed high-quality flex PCBs without breaking the bank. Our pricing strategy ensures that you get the best value for your investment.

Fast Turnarounds - Whether it’s a quick turn PCB or a prototype PCB, Avanti understands the importance of time in the electronics market. Our processes are geared to deliver with swiftness and accuracy.

Prompt, Customer Service - Our team is always ready to assist, guide, and resolve any queries, ensuring a seamless experience for every client.

Diverse Capabilities - From multilayer PCBs to specialized design grids, our diverse capabilities ensure we can handle a myriad of requirements.

Guaranteed Quality - Our commitment to quality is unwavering. Every PCB that comes from Avanti is a testament to our dedication to excellence.

Low Minimums - We understand that not every order is a bulk order. Our low minimum order policy ensures that individual developers and small enterprises can also benefit from our services.

Corporate Values - At Avanti, we believe in a holistic approach. Our corporate values drive us to not only deliver excellent products but also contribute positively to the community and the industry.

Avoiding Common Mistakes in Flexible Circuit Design

Ignoring Mechanical Constraints

Flex PCBs will bend and twist. Ignoring these mechanical actions can lead to premature failures. Avanti’s prototype PCB service lets you test and iterate, ensuring designs are mechanically sound.

Overlooking Thermal Management

Heat can be a flex PCB’s enemy. Ensuring designs accommodate heat dissipation is critical. Avanti offers guidance on incorporating thermal management strategies in your designs.

Neglecting Shielding and Grounding Needs

Electronic noise can disrupt PCB performance. Incorporating proper shielding and grounding is imperative, especially in high-frequency applications.

Improper Connector Selection and Placement

Connectors are the bridges between the flex PCB and the outside world. Choosing the right connector and placing it strategically is essential. Avanti’s design grid can assist in making these pivotal decisions.

Benefits of Prioritizing Flex PCB Best Practices

Improved Functional Reliability: Proper design considerations lead to PCBs that consistently perform at their peak.

Reduced Production Costs in the Long Run: Fewer iterations mean less wastage, ensuring a better return on investment.

Enhanced Product Reputation and Customer Trust: A well-designed product garners positive reviews, leading to trust and brand loyalty. With Avanti's guaranteed quality, this is always within reach.

Flex PCB design considerations are not just technicalities; they're crucial pillars ensuring the success of the final product. As the electronics world leans more towards compact and flexible solutions, the demand for impeccable flex PCB designs will only grow. Avanti Circuits, with its emphasis on quality, customer service, and rapid turnarounds, is poised to be your ideal partner in navigating this challenging yet rewarding landscape.

References & Further Reading

- PCB Facts - Dive deep into the nuances of PCBs with Avanti’s comprehensive guide.

- PCB Glossary - Decode the jargon of the PCB world with our exhaustive glossary.