What Is The Difference Between PCB vs PCBA?

If you are new to the world of printed circuit boards, you may be seeing a lot of terminology. A PCBA board may have been mentioned from time to time, as well as a PCB. However, it’s not always clear what the difference between the two is. Don’t worry, we can help you.

We have been in the printed circuit board industry for almost 40 years. We can help you with all of your printed circuit board queries. Contact us today at [602 866 7227](tel:602 866 7227). We are here to help you with your queries.

What Is A PCB?

A Printed circuit board (PCB) is a layer or foundation that a range of electronic components can be mounted on. A range of components is added to create a functional circuit board. The PCB contains a trace, also known as a conductive pattern and a substrate. The substrate may be made of epoxy resin, a tough material that can withstand a lot of heat. The pattern that the epoxy resin makes up can be inscribed or printed on some epoxy glass, depending on the design required.

Printed circuit boards can have a single layer, double layer, or as many as 6 to 8 layers. The more layers they have the more complex the design is.

- Single layer printed circuit boards – PCBs such as these are some of the simplest PCBs. They are covered in a single layer of the chosen conducting material. In addition to this, single layer printed circuit boards also contain a solder mask. The components are marked using a silkscreen.

- Double-layer printed circuit boards – A double-layer printed circuit board has two layers of conducting material, on the top and the bottom of the PCB. A circuit board such as this is very flexible. In addition to this, it ensures that the overall size of the PCB is smaller than it would otherwise be. This makes PCBs such as this ideal for smaller devices.

- Multi-layer printed circuit boards – With multiple conductive layers, multi-layer printed circuit boards tend to be used in very complex applications.

No matter why you need a printed circuit board, we can help you. We are a team of manufacturing professionals who can give you exactly what you’re looking for. We can help you to get the PCBs that are ideal for you and your company. Please feel free to contact us today so that we can help you.

What Is A PCBA?

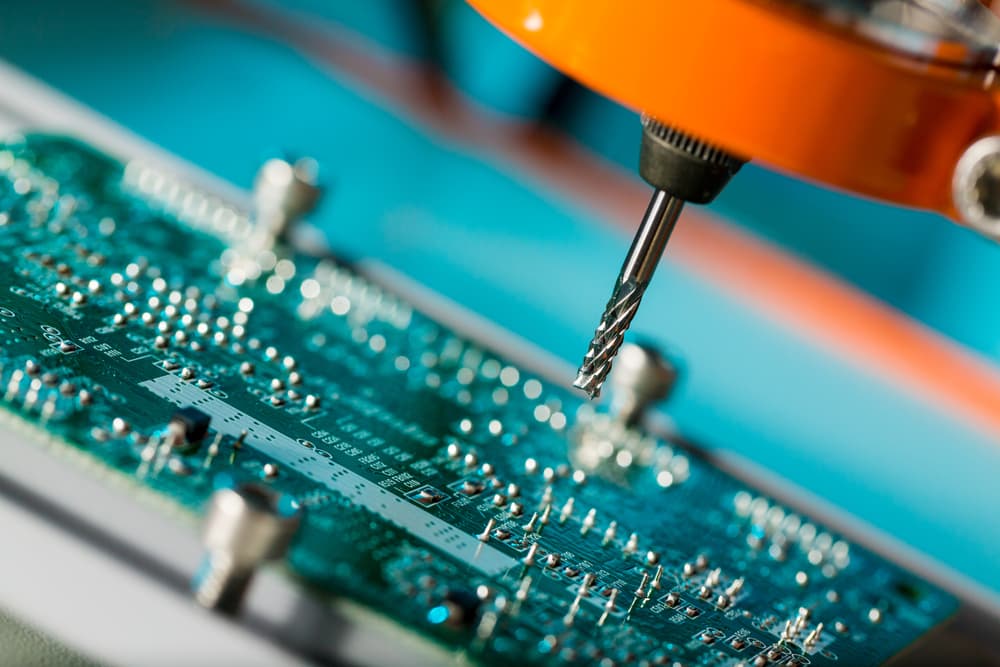

A PCBA relates to the printed circuit board assembly. It includes the whole manufacturing process from a blank circuit board to a completed one. The blank or “unpopulated” circuit board would have undergone the Plated Through Hole and Surface Mounted Technology stages. These stages ensure that the required components are added to and soldered onto the blank printed circuit board. After solder and component placing has taken place, the printed circuit board will undergo different stages of quality control inspection.

A PCBA is basically a finished printed circuit board. It has all the required components and materials.

− PCBAs and the components used

During the assembly process, a printed circuit board is populated with a range of electronic components. The components used will depend on the design. Through-hole technology may be used to ensure that all of the electrical components that are used will be correctly and firmly mounted to the PCB. The components that are attached are always surrounded by conductive pads. The components will be placed on the printed circuit board, ensuring that the pins are perfectly aligned with the surrounding conductive pads. If there are electronic components anchored to one side of the printed circuit board they will need to be placed in a specific way. The components will need to be glued onto the board before any soldering takes place. This is simply to make sure that the components remain exactly where they need to be.

− Testing a PCBA

As soon as we have manufactured a PCBA, we will test it. We always test every single circuit board that we make. We want them to reach you in perfect condition. This is so that you can insert your PCBAs into the required device. If we find that a PCBA is not up to our high standards we will endeavor to correct the fault. As soon as the fault has been corrected we will check the PCBA once more.

When we test our PCBAs we:

- Switch the power off and visually inspect the board. Alternatively, we may use an optical inspection tool that has been automated

- Keeping the power off, we undertake analog signature analysis. This process is also known as “power-off testing”

- The next stage is to switch the power back on and undertake in-circuit testing

- The final stage of the testing process involves undertaking a functional test. A test such as this ensures we know that the PCBA functions in the way that it is supposed to function.

As you have already seen, we make sure that all of the PCBAs that we manufacture work well. We think it’s important that you always receive high-quality PCBAs every time. This is why we always go a little further for you. It’s no wonder that we have many returning customers. They trust us to get the job done correctly each and every time. They know that we always work to the highest standard. You can trust us to do the same when we manufacture PCBs and PCBAs for you.

What Types Of Materials Are Used For Each?

There is a range of materials used for both printed circuit boards and printed circuit board assembly. The most common material that is used is the substrate material. This is usually either composite epoxy or fiberglass. Please let us know if there is a substrate material that you would specifically like us to use.

− Conducting material

Conducting material tends to be placed on either one or both sides of the PCB. In most cases, copper is used as the conducting material. The circuit boards are etched or plated onto the substrate material. This is always done according to the design. The substrate material is usually made of copper.

− Adding circuits

During the next stage of manufacturing, the circuits are added. They are coated with some tin-lead. This material is used to help prevent oxidation, ensuring that the circuits last longer than they otherwise would.

− Adding tin-lead

Tin-lead is also added to the contact fingers that are located on a PCB’s outer edges. Again, this is to help prevent oxidation. Other materials may also be added such as gold or nickel. This is used to increase the conductivity, which ensures each PCB works so much more effectively.

− PCBs and PCBAs

Each of these materials is used on both printed circuit boards and in the printed circuit board assembly process. The materials have their own separate functions and help to ensure that the PCB or PCBA works well.

What Are Each Used For?

Printed circuit boards and PCBAs are used in a wide range of industries such as the:

- Aerospace industry

- Automotive industry

- Medical industry

- Military

PCBs and PCBAs are used in many different electronic devices. Most homes in this country will have at least a few devices in every room that contain a PCBA. Some of these devices include:

- Cell phones

- Computers

- Radios

- Televisions

- Calculators

- Printers

- Lighting systems

- Kitchen appliances

- Laundry room appliances

- Pacemakers

- Medical imaging systems

- Engine management systems

- Telecom towers

- Satellite systems

- Data storage equipment

As you can see, PCBs and PCBAs are used in a lot of industries and devices. It’s clear then, that without PCBs and PCBAs, we would be unable to operate many different devices.

− High-quality PCBs and PCBAs

We are proud to offer you our very high-quality printed circuit boards and PCBAs. We have been working in this industry for almost 40 years. We can assure you that we are more than capable of manufacturing high quality printed circuit boards for you.

We always work with all of our customers in mind. We want all of our customers to be completely happy with every aspect of our printed circuit boards, before and after assembly. We think you would like us to work this way. This is why we put all of our customers at the heart of all that we do.

Contact Us Today For A PCBA Consultation

Whether you would like to order a PCBA board or two or some PCBs, we can help you. We are a team of trusted professional PCB manufacturers. We can help you get exactly what you are looking for. Talk to us today about what it is you need, we will be more than happy to help you. We can also look over your PCB design should you wish us to. We can make sure that you’re happy with all that we do, every step of the way.

Contact us today for a PCBA consultation so you’re one step closer to getting exactly what you need. Call us at [602 866 7227](tel:602 866 7227). We are here to help you.