Single Sided PCB Manufacturer

Here at Avanti Circuits, we are proud to be a major manufacturer of printed circuit boards. We manufacture different circuit boards to fulfill a range of requirements. We are also a single sided pcb manufacturer that can give you exactly what you are looking for. With more than 35 years in this industry, we are the #1 manufacturer of USA-made PCBs. We’re trusted by some of the world’s biggest names, and we can meet your printed circuit board needs. If you are looking for a manufacturer to provide you with a high quality single sided PCB, we can help you. Contact us today for a single sided PCB quote. You can contact us at 602- 866-7227. We are here to meet your single sided PCB needs. Call us today, we’re a friendly team who want to help you as much as possible.

What Is A Single Sided PCB?

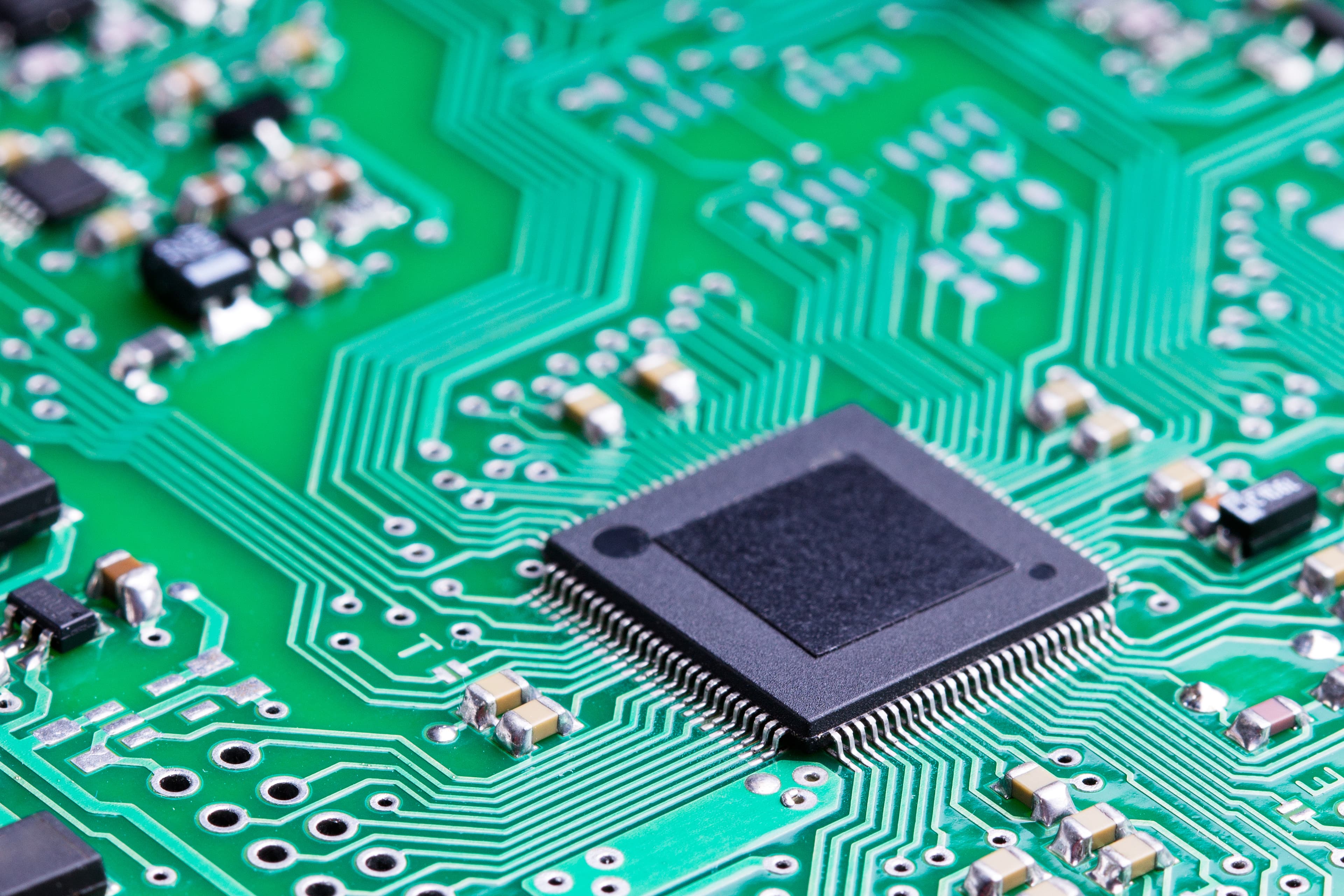

A microcontroller on an electronic board

A single sided PCB is perhaps the most basic type of PCB. Consisting of just one layer of conductive copper, the copper is located above the substrate. The components that are used on a printed circuit board such as this are mounted or soldered onto one side of the PCB. You can see the etched circuit board on the other side.

This type of PCB is very easy to design and make. In addition to this, they tend to be the most cost-effective too. As single sided printed circuit boards have a single conducting layer, the conductive paths are unable to overlap or cross. This means that they can take up a lot of space. Because of this, single sided printed circuit boards are ideal for many low-density needs. This means that they can be used in timing circuits, power supplies, FM radios calculators, LED lighting boards, and other low cost electronic products.

Advantages Of Single Sided PCB’s

Some of the advantages of single sided printed circuit boards include:

- They’re ideal for low-density needs such as radios, calculators, and other electronic products that cost very little

- They’re easy to design as they are not very complex and they can be used in a variety of applications

- They’re easy to manufacture, again, because they’re not very complex, thanks to the limited number of components that are needed

- Repairs are usually very easy as there is very little to go wrong at any time

- Thanks to their cost-effectiveness, they are ideal for large volume orders. This is thanks to their very basic designs, meaning they can be the best choice for circuits that are low density and relatively simple

- There tends to be a lower risk of manufacturing issues when compared to other PCBs thanks to their basic designs

- Single sided PCBs can be made of various materials, ensuring they offer the flexibility that a lot of people require

There are some real advantages of single sided printed circuit boards. It’s no wonder that they are frequently used in a range of industries. If you would like us to manufacture single sided printed circuit boards for you, please contact us. We can provide you with a quote.

The Working Principles Behind Single Sided PCB’s

The working principle behind single sided PCBs is to specifically isolate the copper foil’s conductive layer. The isolation needs to take place on the surface with the base insulating material. This is to ensure that the current is able to flow in the components that have been added to the printed circuit board. The idea is that the current can flow along the designed route so that a variety of tasks can be completed. These tasks include:

- Attenuation – this is the reduction of the force, value, or effect of something

- Demodulation – this is used to separate information or a signal from a modulated carrier

- Amplification – this is used to increase the volume of sound that is produced

- Encoding – this ensures that it is possible to encode and then transmit recorded information

The tasks that the printed circuit board is required to do will help the FM radio, for example, to work as desired. Single sided PCBs are ideal for a range of products that millions of people use every single day. Contact us if you would like us to manufacture some single sided PCBs for you.

Materials Used

Printed circuit boards are typically manufactured by using a range of different materials. The insulating material which is known as the “Substrate” is commonly made from reinforced glass fiber (fiberglass). However, it can also be made from phenol resin or epoxy resin. A copper layer is laminated onto the substrate and into the pattern desired.

Copper circuits are coated with tin-lead. This is to ensure that no oxidation takes place. In addition to this, the tin-lead helps to aid the soldering process. Organic solderability preservative or chemical gold can be used. Next, contact fingers are added and plates with both electrolytic gold and nickel. This ensures that conductivity is good. When conductivity is good, the PCB can be used as desired.

There are other materials that can be considered. These materials can include carbon connections, silver-cross, carbon contacts, and a range of solder masks. The solder masks can be a photo-imageable process or silkscreen.

- CEM1/CEM3 – CEM1 is a composite material. It is made up of paper core and woven glass fabric. These materials are combined with epoxy resin. This mix of materials ensures that it has a high strength, is very flexible, and has great electrical properties. In addition to this, it provides excellent mechanical properties. CEM3 is similar to FR4 (See below), except that it is made from “flies” rather than woven glass fabric. With a milk-like color, CEM3 is smooth and is considered to be an excellent replacement for FR4. Flame-retardant, and made from epoxy, plate glass, copper-clad material, CEM3 can be used in a range of electronics.

- FR1/XPC – These materials tend to be used in devices that don’t need a lot of technology to run. Made of phenol and paper, they are easy to build but they are not very resistant to heat. FR1 is still being used but very rarely, it is slowly being replaced by FR4 and CEM1/FR3 materials.

- FR4 – Printed circuit boards need to be heat resistant. FR4 has higher heat resistance than FR1. This is due to its different layer compositions. An FR4 printed circuit board’s core is manufactured from fiberglass epoxy laminate. This material tends to be the most common material used. Using 8 layers of glass fiber as standard, FR4 has a maximum temperature somewhere between 248 – 266 degrees Fahrenheit. However, this typically depends on the filler and brand used.

Please feel free to ask us any questions you may have about the materials we use.

Other materials that are used include components. These components and their functions include:

- Connectors – These are used to connect circuit boards (Although they are not needed in single sided printed circuit boards)

- Electrical boundary – An electrical boundary is used to determine the circuit board’s size. No components should exceed the boundary.

- Filling – Copper coating is typically used for ground wire networks. This helps to reduce impedance.

- Mounting hole – A mounting hole is used to fix the circuit board in place so that it does not move around when the product is being used.

- Pad – Pads are metal holes which are used to solder component pins. Pads are essential as they can help the PCB to work effectively at all times.

- Vias – Both non-metal and metal pins are used to connect pins between different layers. (Although they are not needed in single sided printed circuit boards)

- Wire – A wire is an electrical copper film. This copper film is used to ensure the component’s pins are connected. Wires, therefore, help the PCB to work at all times. No connection means the PCB does not work very well, if at all.

As you can see, a range of materials is used to manufacture a single sided printed circuit board. Different manufacturers may use different materials based on their preferences, meaning some PCBs may be slightly different when compared to others. Please contact us if you have any questions about our single sided PCBs and/or the materials that we use. If you’re looking for something in particular, we may be able to help you.

Single Sided Vs Double Sided

There are quite a few differences between single sided and double sided printed circuit boards. Some of these differences include:

Power – Single sided PCBs are typically used in electrical items that do not need much power. However, their double sided counterparts are used to increase the substrate’s conducting power. The through-holes that exist on a double sided PCB are mounted on the top and bottom. In addition to this, they are connected through holes so that they remain attached.

Layers – Single sided printed circuit boards have a single layer of substrate. Double sided printed circuit boards have more than one layer, but fewer than multi-layer PCBs. Single sided boards have 3 main layers. These layers are assembled on the board and consist of a conductor material, silkscreen, and a solder mask. When it comes to a double sided PCB, there is a conductive path on both of the sides. Both of these sides consist of copper, a solder mask, and silkscreen.

Cost – When it comes to the cost of a single sided printed circuit board, they tend to be very cost-effective. This is thanks to their basic design and ease of manufacture. Double sided printed circuit boards have circuitry that is much more complex. This is because there is a lot more space to work with. As there is more space to work with, boards such as these are used for much more advanced electronics and some demanding applications. In addition to this, with the ability to use both sides of the PCB means the size of the circuit board is reduced. Double sided printed circuit boards can be less expensive than some PCBs thanks to the ability to add more components in a relatively small space.

Use – Single sided circuit boards tend to be used in low cost electronic items. However, double sided PCBs are often used in more complex items that require greater power and better protection against heat or fire. They are also used where there are demanding applications or advanced electronics.

CONTACT US TODAY FOR A SINGLE SIDED PCB QUOTE

We can be your single sided pcb manufacturer. A trusted manufacturer, we are here to help you.

With more than 35 years in this industry, we are the #1 manufacturer of USA-made PCBs. We’re trusted by some of the world’s biggest names, and we can meet your printed circuit board needs. If you are looking for a manufacturer to provide you with a high quality single sided PCB, we can help you. If you order single sided PCBs from us, you’ll be putting Americans to work.

Contact us today for a single sided PCB quote. You can contact us at 602- 866-7227. We are here to meet your single sided PCB needs.